Until recently, much of the research and innovation on sustainable construction has been focused on the operational emissions associated with the building, particularly on improving thermal performance. However, there is increasing recognition that capital emissions, those emitted during the manufacture of construction materials and those embodied in the materials themselves, are of similar importance. As heating systems are electrified and countries decarbonise, their electricity generation and the emissions associated with heating and lighting decrease. This in turn increases the relative importance of capital emissions1. In addition, the lifetime of a building determines the split between operational and capital. Operational emissions are often calculated over the entire design life, however many buildings end up being demolished sooner than planned2. Concrete and Steel are the main source of capital emissions, and these industries are working towards decarbonisation, but rely heavily on carbon capture and storage to reach their targets3,4. Other sources recognise the need for material efficiency measures, but do not predict that they will be implemented in time to meet 2050 net zero targets5.

Early research by the ACORN team has highlighted the importance of categorising the opportunities for material efficiency in construction to avoid double-counting wherever possible. Areas where there are opportunities to reduce waste and improve efficiency in concrete construction are:

- Choice of Structural Form: Choice of grid size, length of span etc greater than required

- Overdesign: Design specifying more material than required for structural purpose (e.g. prismatic beams)

- Overspecification of Structure: Structure designed for loads greater than actually experienced

- Overspecification of Materials: Choice of materials with greater strength than required

- Over-Ordering: Ordering materials in excess quantity than required for construction (e.g. to avoid running out)

- Over-Delivery: Delivery of materials in excess quantity or specification than ordered (e.g. overstrength concrete)

- Onsite Waste: Materials delivered to site but not used for construction

- Over-binding: Concrete delivered with same strength performance but excess binder index

- Excess Clinker: Concrete delivered with same binder index, but a greater proportion of clinker than required

- Efficiency of Clinker Plant: Clinker produced at a plant below the best-available-technology

- Efficiency of Clinker Production: Clinker produced while plant is operating below best-observed performance

- End of Life Recovery: Emissions resulting from (or mitigated by) treatment of waste at end-of-life

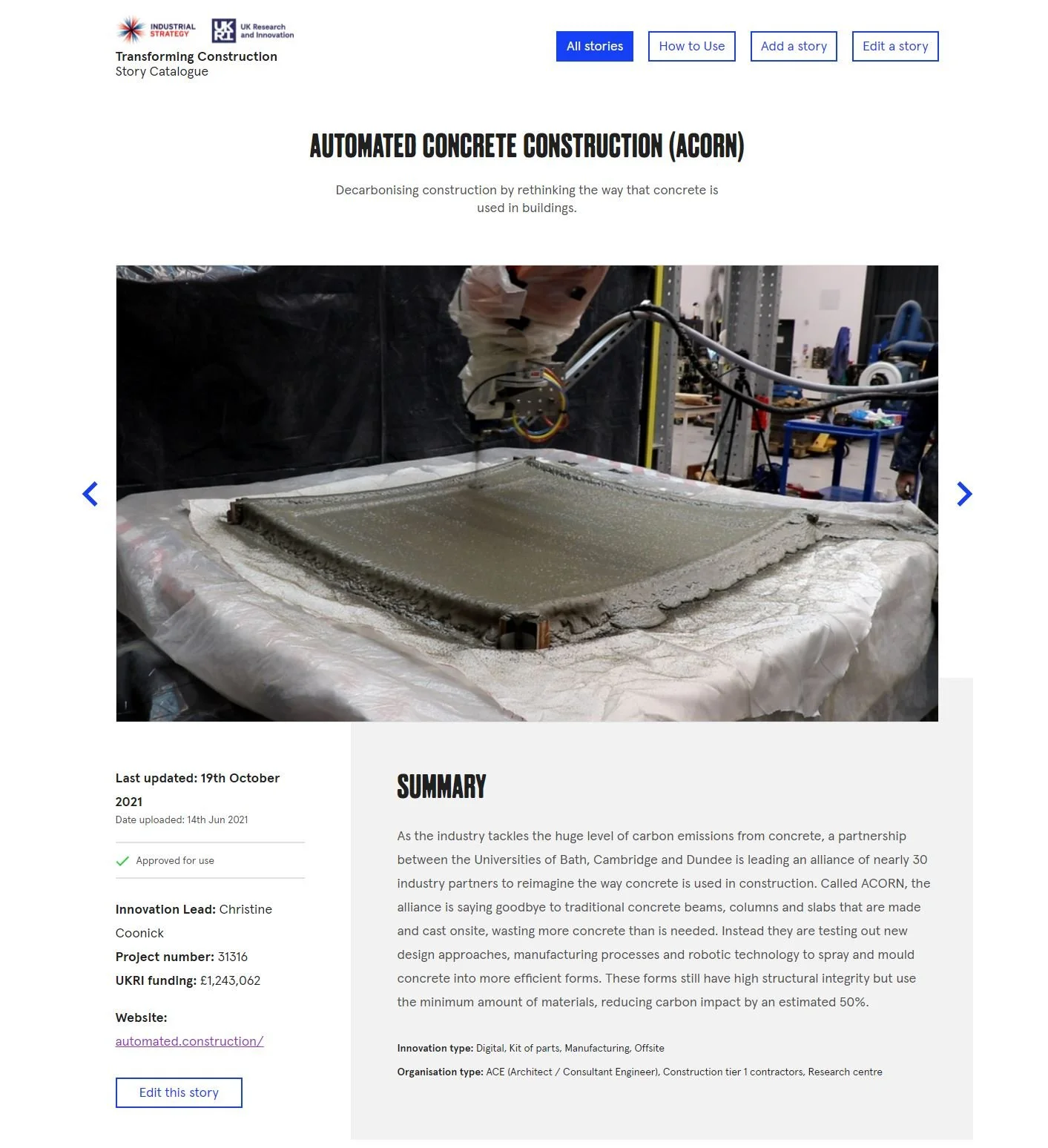

The estimated improvements achievable varies depending on material source, construction stage, and construction process. One of the biggest opportunities is in the Overdesign category, where waste can be as high as 50%. It is here that the ACORN project can deliver substantial advantages over conventional processes and designs.

The research team are not alone in seeing the huge opportunities for cost and carbon reduction, and productivity increase, that an ACORN approach can deliver. The project is working closely with its 12 Industry Steering Partners and another 12 Industry Project Affiliates, companies of all sizes spanning the entire AEC industry who have pledged active support for the project’s vision. If your company would be interested in signing up (for free) as an ACORN Affiliate, please get in touch via acorn@automated.construction or check out the rest of our website.