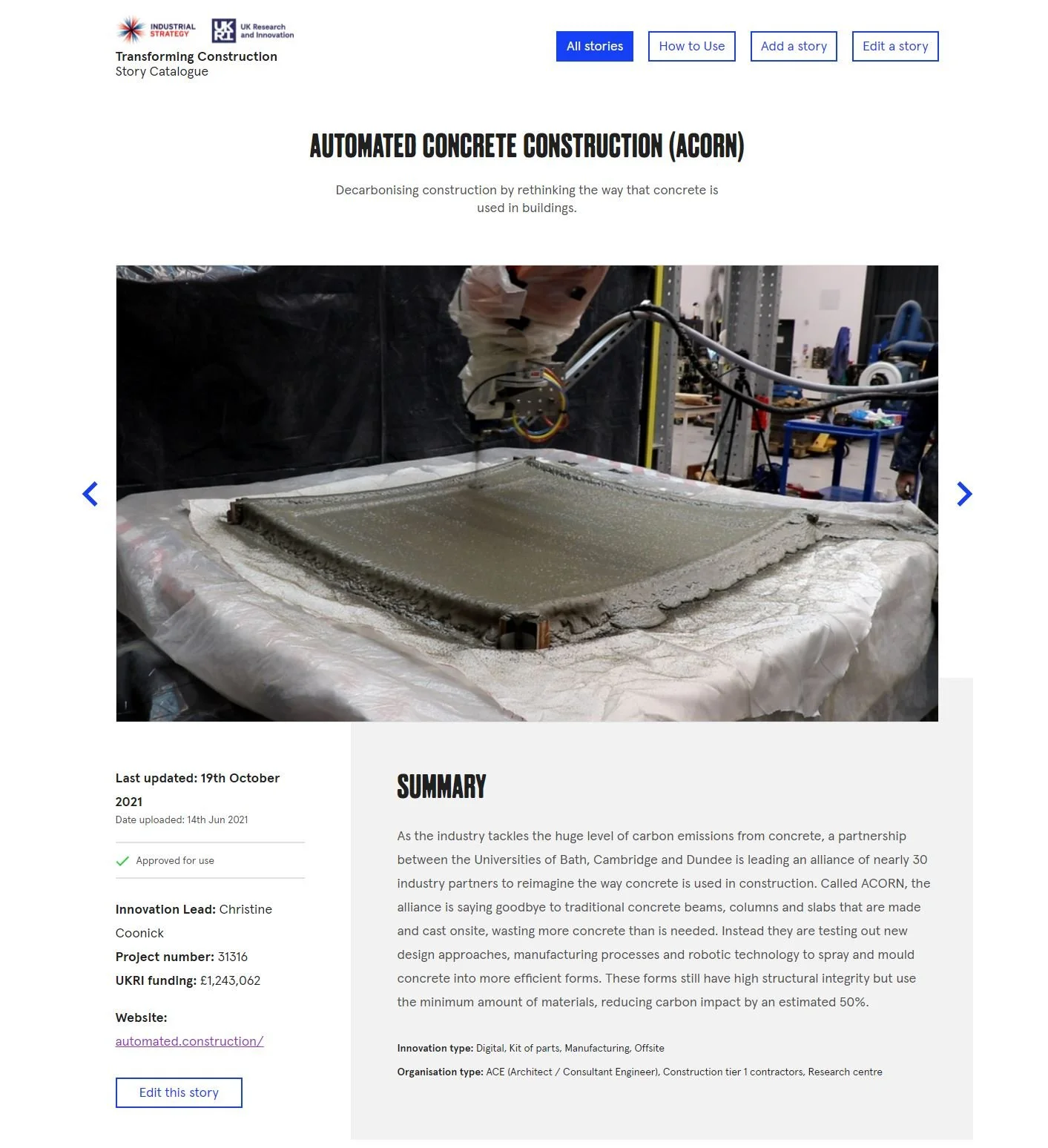

We are delighted to welcome two new Postgraduate Researchers to the ACORN Team: Anna Perepechay and Maxime Pollet!

Anna is joining the ACORN team to research a PhD under the supervision of Saverio Spadea the University of Dundee. Her main research interest centres around the potential of concrete to become an innovative, low-carbon construction material.

Anna holds two Bachelor’s degrees in Civil Engineering, one obtained in Denmark and another one in Poland, and Master’s degree in Structural and Foundation Engineering from the Heriot Watt University in Scotland. She is a member of the Institution of Civil Engineers and the Institution of Structural Engineers. She has over 6 years of the professional experience working as a structural engineer in multidisciplinary consultancies in London and in Edinburgh.

In 2019, Anna was awarded the Construction Scotland Innovation Centre Collaborative Postgraduate Funding for a dissertation that had significant relevance to the construction sector and a high degree of originality and innovation potential.

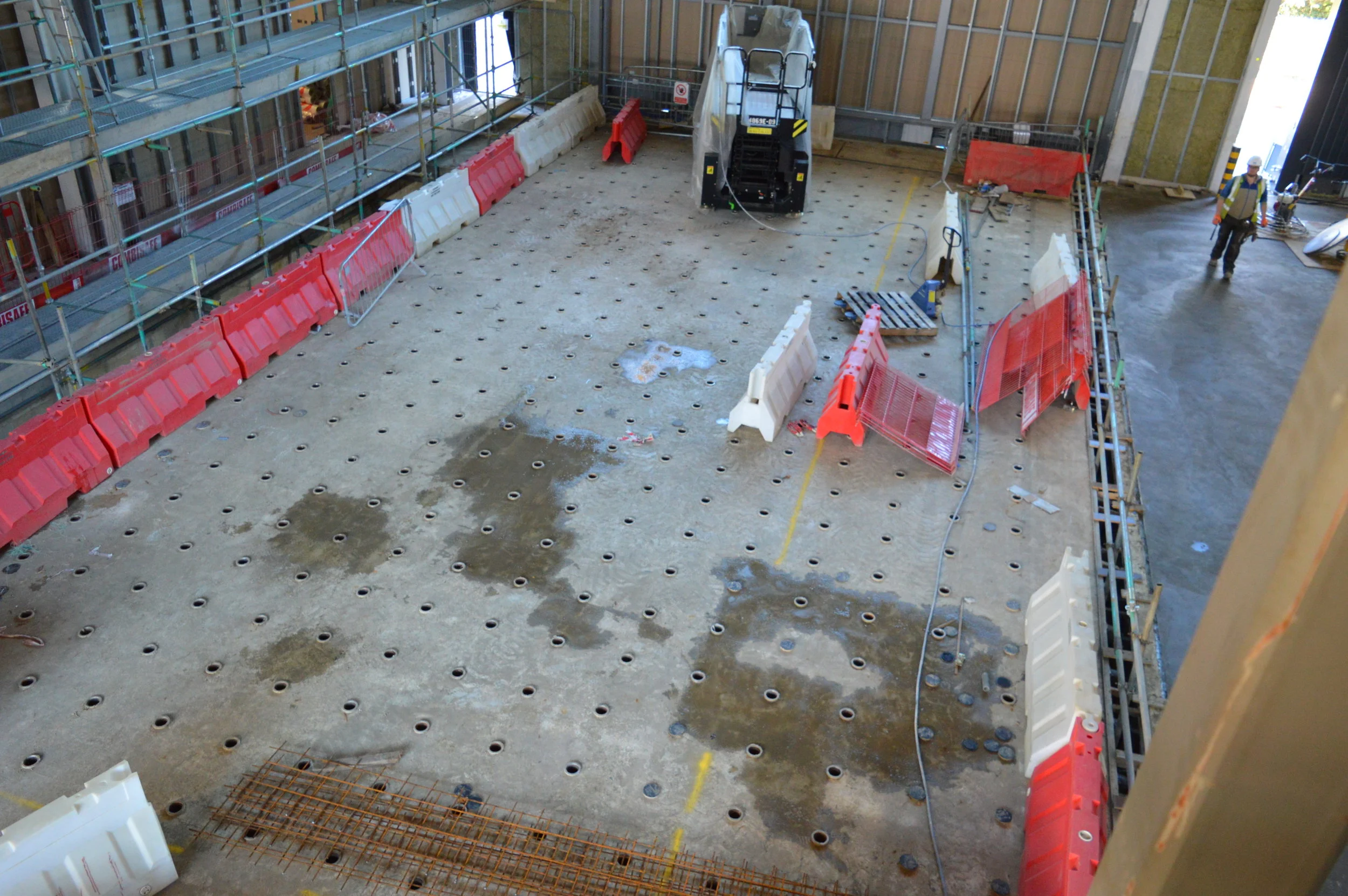

Maxime is joining the ACORN team to research a PhD under the supervision of Paul Shepherd at the University of Bath. He will notably develop a Digital Twin of the Demonstration Building, which will be built at the BRE Innovation Park in Watford.

Before joining ACORN, Maxime graduated as a Civil Engineer from the Edinburgh Napier University in 2019. His Master’s thesis was focused on the development of an algorithm for the form-finding of cable net structures. Prior to this, Maxime studied two years in Grenoble and graduated from a technological degree in Civil Engineering and Sustainability.

Maxime also gained practical on-site experience during two placements. Thus, he worked two months as a project manager in Montfavet (France) for VINCI Construction, where he supervised the finishing works of two residential buildings.